Home > FR4/G10 Fiberglass epoxy sheet

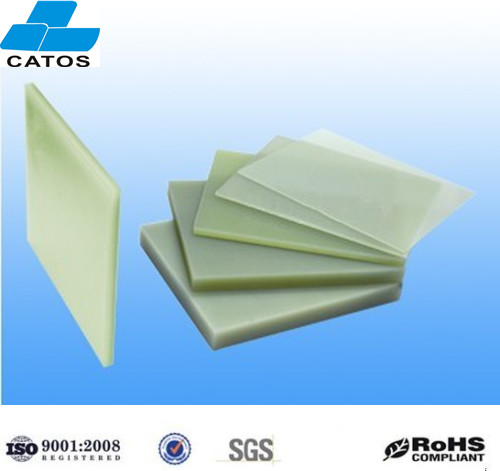

Epoxy Fiberglass Laminted Natural Green FR4 Sheet

Epoxy Fiberglass Laminted Natural Green FR4 Sheet

Model: FR4-Light Green

1.Free samples, NO MOQ required

2.High mechanical properties under high temperature

3.good electrical properties under dry and humidity conditions

1.Free samples, NO MOQ required

2.High mechanical properties under high temperature

3.good electrical properties under dry and humidity conditions

4. Flame Retardant

5.Heat-resistance prosperity

- Product Detail

- Inquiry

Description

This product is a kind of laminated board formed through heat pressing after the electric industry fiolax cloth dips into epoxy resin. It is suitable as the mechanical, electric and electronic insulation structural components which are used under room and middle temperatures with a certain mechanical performance and electric performance requirement.

Characteristics

-Excellent mechnical strength

-Good insulation function

-High temperature resistant

-Stable size

-Good ablity against acid ,alkali and solvent

-Hard and durable

-Good adhesive properties in the surface

-Waterproof

Applications

1.Cabinets .

2.Railway

3.Automobile

4.Transformers

5.Electric switches

6.Control boxes

7.Electric motors

8.Medical appliances

9.Household appliances

Technical Data Sheet

Technical Data

Method of Verification

Unit

3240

I.Physical Properties

Density

ISO 1183

g/cm3

2.0~2.1

Water absorption 24hrs

ISO 62

%

0.05~0.15

III.Thermal Properties

Max. service temperature -Short term

ISO 75-2

ºC

/

Max. service temperature - Long term

ISO 75-2

ºC

130~140

Coefficient of Thermal Expansion-LW

ISO 11359

m/K

/

Coefficient of Thermal Expansion-CW

ISO 11359

m/K

/

Thermal Conductivity

ISO 11359

W/(m·K)

2.2~2.5

Flammability

UL 94

Class

V-1

II.Mechanical Properties

Tensile strength at yield

ISO 527-2

MPa

≥220

Tensile strength at break

ISO 527-2

Mpa

/

Hardness Rockwell

DIN 53505

120-125

Izod impact strength

ISO 179

kJ/m2

≥33

Bending Strength

ISO 527-2

Mpa

/

Flexural strength-LW

ISO 179

Mpa

≥314

Flexural strength-CW

ISO 179

Mpa

≥216

Adhesive Strength

ISO 179

N

5600

Compression strength-LW

ISO 179

Mpa

≥350

Compression strength-CW

ISO 179

Mpa

≥147

IV.Electrical Properties

Volume resistively

IEC 60093

Ohm (Ω) * cm

1.3x1014

Surface resisively

IEC 60093

Ohm (Ω)

3.5x1012

Electric strength- LW

VDE 0303

kV/mm

≥14.2

Breakdown Voltage-CW

VDE 0303

kV

>34

Relative dielectric coefficient

VDE 0303

/

≤4.7

Dielectric Loss mudule

VDE 0303

50HZ

≤0.04

Arc resistance

VDE 0303

S

/

NOTE: 1 g/cm3 = 1,000 kg/m3, 1 Mpa = 1 N/mm2, 1kV/mm = 1 MV/m

Description

This product is a kind of laminated board formed through heat pressing after the electric industry fiolax cloth dips into epoxy resin. It is suitable as the mechanical, electric and electronic insulation structural components which are used under room and middle temperatures with a certain mechanical performance and electric performance requirement.

-Excellent mechnical strength

-Good insulation function

-High temperature resistant

-Stable size

-Good ablity against acid ,alkali and solvent

-Hard and durable

-Good adhesive properties in the surface

-Waterproof

Applications

1.Cabinets .

2.Railway

3.Automobile

4.Transformers

Technical Data Sheet

| Technical Data | Method of Verification | Unit | 3240 |

| I.Physical Properties | |||

| Density | ISO 1183 | g/cm3 | 2.0~2.1 |

| Water absorption 24hrs | ISO 62 | % | 0.05~0.15 |

| III.Thermal Properties | |||

| Max. service temperature -Short term | ISO 75-2 | ºC | / |

| Max. service temperature - Long term | ISO 75-2 | ºC | 130~140 |

| Coefficient of Thermal Expansion-LW | ISO 11359 | m/K | / |

| Coefficient of Thermal Expansion-CW | ISO 11359 | m/K | / |

| Thermal Conductivity | ISO 11359 | W/(m·K) | 2.2~2.5 |

| Flammability | UL 94 | Class | V-1 |

| II.Mechanical Properties | |||

| Tensile strength at yield | ISO 527-2 | MPa | ≥220 |

| Tensile strength at break | ISO 527-2 | Mpa | / |

| Hardness Rockwell | DIN 53505 | 120-125 | |

| Izod impact strength | ISO 179 | kJ/m2 | ≥33 |

| Bending Strength | ISO 527-2 | Mpa | / |

| Flexural strength-LW | ISO 179 | Mpa | ≥314 |

| Flexural strength-CW | ISO 179 | Mpa | ≥216 |

| Adhesive Strength | ISO 179 | N | 5600 |

| Compression strength-LW | ISO 179 | Mpa | ≥350 |

| Compression strength-CW | ISO 179 | Mpa | ≥147 |

| IV.Electrical Properties | |||

| Volume resistively | IEC 60093 | Ohm (Ω) * cm | 1.3x1014 |

| Surface resisively | IEC 60093 | Ohm (Ω) | 3.5x1012 |

| Electric strength- LW | VDE 0303 | kV/mm | ≥14.2 |

| Breakdown Voltage-CW | VDE 0303 | kV | >34 |

| Relative dielectric coefficient | VDE 0303 | / | ≤4.7 |

| Dielectric Loss mudule | VDE 0303 | 50HZ | ≤0.04 |

| Arc resistance | VDE 0303 | S | / |

| NOTE: 1 g/cm3 = 1,000 kg/m3, 1 Mpa = 1 N/mm2, 1kV/mm = 1 MV/m | |||

V. Packing & Delivery

1. PE protective film package; 2. Paper carton and water-proof cloth 3. Pallet and Iron straps position. 4. Weight of a pallet within 300KG . 5.Also we can depends on the requirement of customers |

VI.Fabricating Process of High Temperature Resistance Durostone Sheet

Samples is available to you for free, your inquiry is welcome!

Meanwhile,Processing Guideline and Material Specification is available to you!